Pursuing the Perfect Quality for Cream Croquettes

Cream croquettes, featuring white sauce encased in a crispy coating, are popular menu items that combine a satisfying crunch with a rich, creamy filling. Nissui began producing cream-style croquettes in the early days of the frozen foods business in the late 1960s. Recently, amid intensifying competition in the food service market, we recognized the need to further highlight Nissui's distinctive strengths. To achieve significant quality improvements, we focused on two areas: recipe improvement through "taste component analysis" and development of new manufacturing technology that delivers both superior taste and production stability.

Figure 1. Food service cream croquettes made with new manufacturing technology

Research Approach

Taste Component Analysis

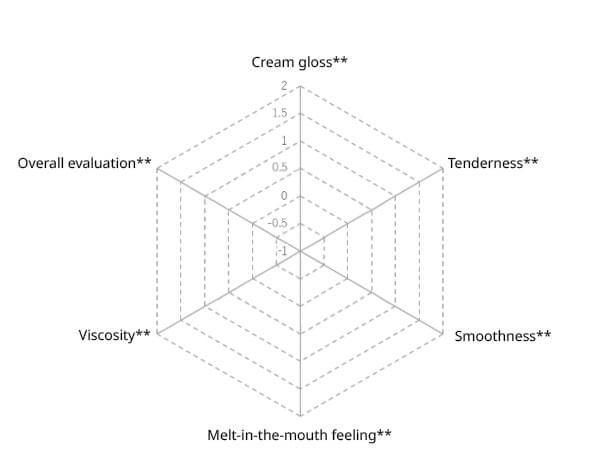

Taste comprises multiple sensory elements including flavor, aroma, texture, dining environment, and physical condition, making it a complex sensory experience. The subjective nature of taste perception makes objective quantification challenging. At Nissui, our research team implemented a new analytical method called "taste component analysis," combining sensory evaluation with statistical techniques to quantify the ideal qualities of cream croquettes. This analysis revealed that texture-related elements--specifically "melt-in-the-mouth feeling," "tenderness," and "smoothness" of the cream filling--were paramount to product excellence, prompting targeted recipe improvements.

Figure 2. Evaluation criteria in "taste component analysis"

Development of New Manufacturing Technology

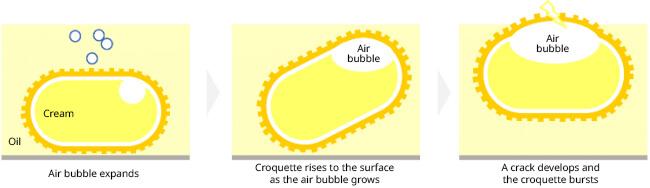

Cream croquettes present significant manufacturing challenges due to their tendency to rupture during the frying process, as the breading breaks and releases the cream filling. Through decades of manufacturing expertise, Nissui has refined production techniques to maintain product integrity. Traditional manufacturing methods, however, compromised the cream's texture, leading to a firmer consistency and reduced smoothness.

Figure 3. Diagram of a cream croquette bursting during frying

After analyzing each production step from a food science perspective, our investigation revealed multiple factors contributing to bursting, with the most significant being the incorporation of several percent of air into the cream during specific processes. Working with our production facilities, we developed new production technology that achieves both superior taste and production stability to achieve the ideal cream croquette texture.

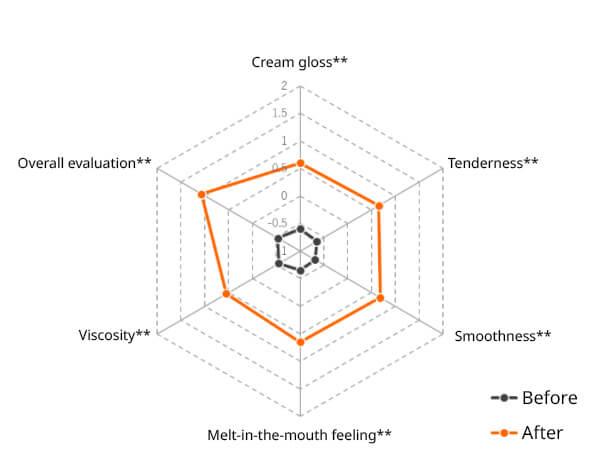

Research Results

In collaboration with our production facilities and Technology Development Department, we developed innovative manufacturing technology that prevents the incorporation of air. After validating both ideal quality and stable production on our manufacturing lines, we successfully launched cream croquettes offering unprecedented quality.

Figure 4. Quality enhancement improvements with new manufacturing technology